Capabilities

Welding

Falstrom welding expertise is recognized in the military industry. Our technicians and engineers are industry leaders.

Our certified welders have experience over a broad spectrum of applications.

- Our certifications include:

- Fusion Welding Aluminum, Steel, Stainless Steel, and HY80 Steel

- MIL STD 248/271/278

- MIL STD 1370/2219:

- AWS D1.1

- AWS D1.3

- AWS D17.1

- Resistance Welding: MIL W 6858

- Processes weldments weighing up to 10,000 lbs.

- High precision rack-mount chassis specifications

Falstrom offers full painting and finish services for our enclosures.

- Painting

- Epoxy Coatings

- Water-bourne Coatings

- Air Dry and Baked Finishes

- Large Cleaning and Processing Tanks

- High Temperature Pressure Washing

- Chemical Film per MIL-C-5541

- Iron Phosphate Coating

- Flame Spray/Metalizing

MIL-SPEC Surface Treatments:

Engineering Services

Falstrom offers a wide range of engineering services including:

- Systems, Electrical, and Mechanical Design

- Computer Aided Design

- Manufacturing Engineering and Optimization

- Welding Consultant

- EMI & Electromagnetic Pulse (EMP) Analysis and Design

- Reliability Analysis and Design

- Component Engineering

Falstom Engineering services can complement customers capabilities with our unique design experience and specialty engineering expertise. Falstrom can design, develop and integrate an enclosure system with foundation subsystems ready for customer integration of primary functions . This includes:

- Transformers

- Power Supplies

- Cable Assemblies

- Cable Management Systems

- EMI Filters and Transient Suppression

- Thermal Management

- Ruggedized Monitors

To further simplify customer design efforts, Falstrom can support customers with full MIL-STD-461 electromagnetic environmental effects designs, intra-system EMC analyses, EMI/EMP control and test plans. Falstrom also offers full component engineering services including parts selection and Specification Control Drawing preparations.

Quality and Certification

Certificate #111364.01Valid: March 18, 2020-2023

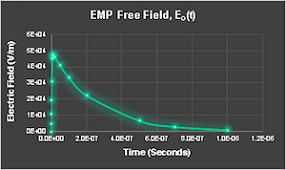

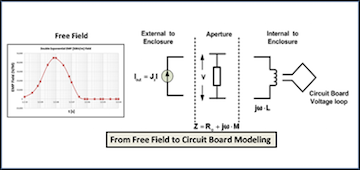

Electromagnetic Environmental Effects

- MIL-STD-461F Conducted Emissions and Susceptibility Analyses

- MIL-STD-461F Radiated Emissions and Susceptibility Analyses

- TEMPEST Design

- Free Field Modeling

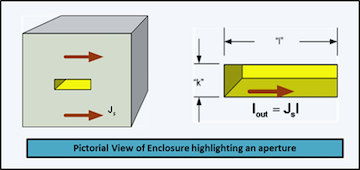

- Coupling of Electromagnetic Fields into Electronic Enclosures

- Modeling of Induced Electromagnetic Fields Internal to Electronic Enclosures

- Circuit Susceptibility and Survivability Models

Additional Capabilities

- Painting

- Epoxy Coatings

- Water-bourne Coatings

- Air Dry and Baked Finishes

- Large Cleaning and Processing Tanks

- High Temperature Pressure Washing

- Chemical Film per MIL-C-5541

- Iron Phosphate Coating

- Flame Spray/Metalizing

MIL-SPEC Surface Treatments:

- Soldering per J-STD-001A (previously MIL-STD-2000A)

Special Processes: